Managing Spare & Assembly Part Logistics: How DistroLogic Brings Precision to Parts Supply

Managing Spare and Assembly Part Logistics: How DistroLogic® Brings Precision to Parts Supply

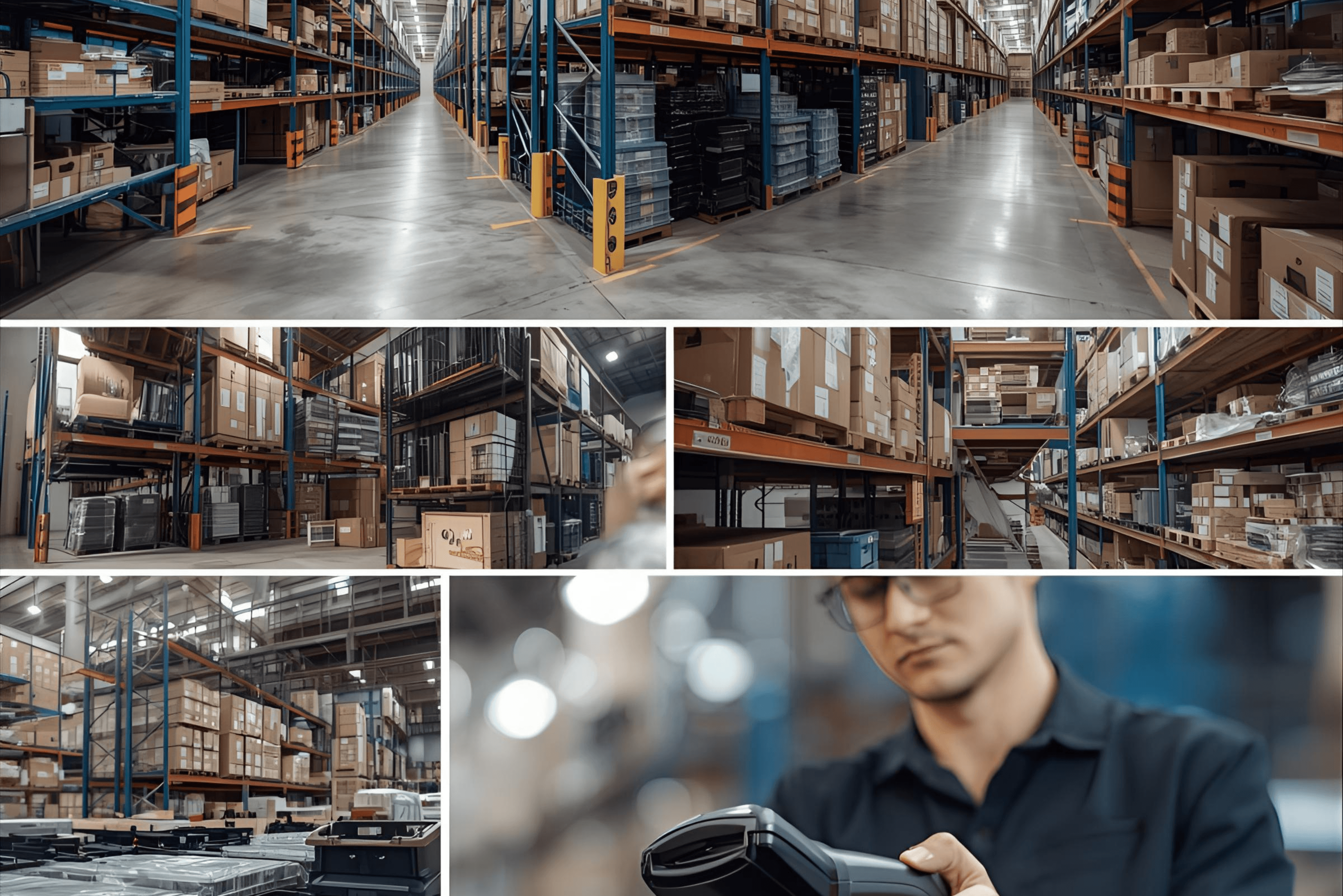

Spare and assembly parts may be small in size, but they carry significant operational importance. When a single component is missing or delayed, entire production schedules can stall. Managing these parts effectively is what separates reactive operations from resilient ones.

At DistroLogic®, we view spare and assembly part logistics as a foundation for reliability. By improving visibility, coordination, and traceability, businesses can maintain momentum even when supply chains get complicated.

Understanding the challenges

Demand variability

Spare parts move on irregular cycles. Some are needed daily, while others sit for months before being called into service. Predicting this movement is difficult, yet essential to keeping operations steady.

Fragmented visibility

When parts are spread across warehouses, vendors, and service centers, it becomes easy to lose track of what’s available and where it sits. Without unified tracking, teams often spend time searching for items instead of using them.

Complex assemblies and kitting

Managing assemblies requires synchronizing multiple components so they arrive together and in the right order. Even small errors in timing or labeling can slow production or service delivery.

Compliance and traceability

Many industries rely on lot or serial tracking for warranty, quality, or regulatory reasons. Losing traceability puts that accountability at risk.

Flexible fulfillment demands

Parts may need to go directly to customers, service technicians, or manufacturing lines. Each scenario calls for a different handling and delivery approach.

DistroLogic®’s approach

Unified tracking

We bring part data from different systems into one centralized view, so every item and serial number can be traced in real time.

Kitting and preassembly support

For products made of multiple components, we manage kits and preassembled units to reduce handling time and improve accuracy.

Automated replenishment

By connecting tracking data to reorder thresholds, we help teams prevent stockouts before they happen.

Lot and serial control

Full traceability ensures warranty and quality compliance, making audits or recalls faster and more reliable.

Adaptive routing

Shipments are coordinated through the most efficient routes—whether that means direct to customer or distribution through service hubs.

The value of precision logistics

When parts are managed well, downtime drops, service speeds up, and teams gain confidence in the data guiding their work. Consistency and accuracy replace reaction and guesswork.

For manufacturers, service providers, and brands that rely on component-based products, this level of visibility and coordination turns logistics into a strategic advantage rather than a background function.

Getting started

Improving spare and assembly part logistics begins with clarity. Understanding how parts move through your system is the first step toward building a process that scales.

DistroLogic® works with teams to identify tracking gaps, integrate existing tools, and design practical workflows for sustained efficiency. The result is a logistics system that supports growth, rather than slowing it down.